The role of palm fiber ash in improving clay bricks

الكلمات المفتاحية:

Clay bricks، Vegetable ash، Recycling، Mechanical properties، Environmental sustainabilityالملخص

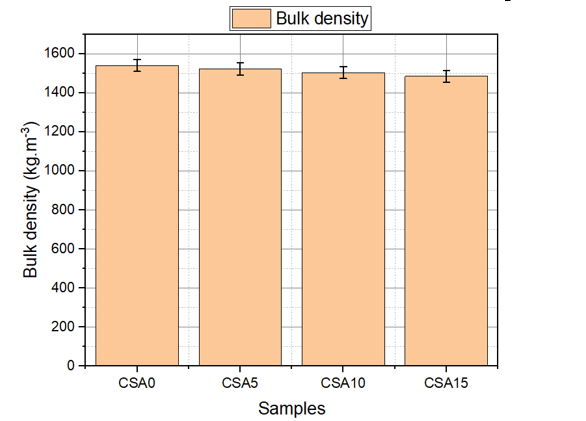

This research examines the effect of adding ash from the combustion of palm fibers to clay bricks to improve their physical and mechanical properties and durability. This research is part of the development of environmentally friendly building materials through the recycling of agricultural waste and the reduction of dependence on natural resources. The methodology involved incorporating different ash ratios (5% to 15%) into a clay and sand mixture, then measuring the bulk density, water absorption rate, and compressive strength according to ASTM standards. The results were analysed using experimental models and compared to reference samples. The results showed that the addition of ash resulted in a 3.7% decrease in density and an improvement in moisture resistance, with a 9.3% decrease in water absorption rate. Compressive strength also increased to 43.75%. The study confirms the feasibility of using ash as an effective additive to improve the performance of clay bricks, while reducing environmental impact and promoting the circular economy.

التنزيلات

المراجع

[1] F. M. Fernandes, P. B. Lourenço, and F. Castro, "Ancient clay bricks: manufacture and properties," in Materials, Technologies and Practice in Historic Heritage Structures, Dordrecht: Springer Netherlands, 2010, pp. 29–48.

[2] Ö. Andiç-Çakır, A. E. Son, S. Sürmelioğlu, E. Tosun, and M. Sarıkanat, "Improvement of traditional clay bricks’ thermal insulation characteristics by using waste materials," Case Stud. Constr. Mater., vol. 15, p. e00560, 2021.

[3] D. Eliche-Quesada and J. Leite-Costa, "Use of bottom ash from olive pomace combustion in the production of eco-friendly fired clay bricks," Waste Manag., vol. 48, pp. 323–333, 2016.

[4] S. Smeu, A. Gal, and C. Badea, "Environmental friendly building materials: Unfired clay bricks," J. Environ., vol. 3, no. 3, pp. 47–50, 2014.

[5] D. Muheise-Araalia and S. Pavia, "Properties of unfired, illitic-clay bricks for sustainable construction," Constr. Build. Mater., vol. 268, p. 121118, 2021.

[6] D. S. Vijayan, A. Mohan, J. Revathy, D. Parthiban, and R. Varatharajan, "Evaluation of the impact of thermal performance on various building bricks and blocks: A review," Environ. Technol. Innov., vol. 23, p. 101577, 2021.

[7] J. I. Knarud, S. Geving, and T. Kvande, "Moisture performance of interior insulated brick wall segments subjected to wetting and drying–A laboratory investigation," Build. Environ., vol. 188, p. 107488, 2021.

[8] S. S. Alterary and N. H. Marei, "Fly ash properties, characterization, and applications: A review," J. King Saud Univ.–Sci., vol. 33, no. 6, p. 101536, 2021.

[9] Kumar, R. Kumar, V. Das, A. A. Jhatial, and T. H. Ali, "Assessing the structural efficiency and durability of burnt clay bricks incorporating fly ash and silica fume as additives," Constr. Build. Mater., vol. 310, p. 125233, 2021.

[10] Pitak, A. Baltušnikas, R. Kalpokaitė-Dičkuvienė, R. Kriukiene, and G. Denafas, "Experimental study effect of bottom ash and temperature of firing on the properties, microstructure and pore size distribution of clay bricks: A Lithuania point of view," Case Stud. Constr. Mater., vol. 17, p. e01230, 2022.

[11] F. Benítez-Vivas, J. P. Gutiérrez-López, J. Torres-Agredo, L. F. Mosquera-Idrobo, and M. F. Díaz-Huertas, "Study on the use of coal bottom ash as a raw material replacement for the production of clay bricks," Ingeniería, vol. 28, no. 3, 2023.

[12] N. L. Bih, A. A. Mahamat, C. Chinweze, O. Ayeni, H. J. Bidossèssi, P. A. Onwualu, and E. E. Boakye, "The effect of bone ash on the physio-chemical and mechanical properties of clay ceramic bricks," Buildings, vol. 12, no. 3, p. 336, 2022.

[13] Mustapha, O. E. Egbanubi, S. O. Abdulraman, and S. A. Adepoju, "Enhancement of mechanical properties of unfired clay bricks using rice husk ash and fibre reinforcement," J. Mater. Eng. Struct., vol. 12, no. 3, pp. 397–408, 2025.

[14] Fidjah et al., "Recycling plastic strips and glass fibers in the compressed earth block," Euro-Mediterranean J. Environ. Integr., vol. 10, no. 1, pp. 237–248, 2025.

[15] F. C. Pa, C. Abdullah, and B. Fazlul, "Extraction of silica from palm ash using citric acid leaching treatment: Preliminary result," Adv. Mater. Res., vol. 795, pp. 701–706, 2013.

[16] Srisuwan, S. Sompech, C. Saengthong, S. Thaomola, P. Chindraprasirt, and N. Phonphuak, "Preparation and properties of fired clay bricks with added wood ash," J. Met., Mater. Miner., vol. 30, no. 4, pp. 84–89, 2020.

[17] G. Cultrone and E. Sebastián, "Fly ash addition in clayey materials to improve the quality of solid bricks," Constr. Build. Mater., vol. 23, no. 2, pp. 1178–1184, 2009.

[18] Z. Rahman, H. Nazarah, W. Idris, and T. Lihan, "Mechanical characteristics of developed brick from drinking water sludge under different firing temperatures and rice husk ash contents," Sains Malaysiana, vol. 52, no. 7, pp. 2115–2126, 2023.

[19] S. Abbas, M. A. Saleem, S. M. Kazmi, and M. J. Munir, "Production of sustainable clay bricks using waste fly ash: Mechanical and durability properties," J. Build. Eng., vol. 14, pp. 7–14, 2017.

[20] B. Sivagnanaprakash, P. Murthi, and A. Sekaran, "A study on structural applicability of flyash bricks with quarry dust–An ecofriendly alternative for clay bricks," Pol. J. Environ. Stud., vol. 24, no. 2, pp. 695–699, 2015.

[21] Srisuwan and N. Phonphuak, "Physical property and compressive strength of fired clay bricks incorporated with paper waste," J. Met., Mater. Miner., vol. 30, no. 1, pp. 103–108, 2020.

[22] P. Muñoz, V. Letelier, L. Muñoz, M. A. Bustamante, O. Gencel, and M. Sutcu, "The combined effect of bottom ashes and cellulose fibers on fired clay bricks," Constr. Build. Mater., vol. 301, p. 124307, 2021.

[23] S. Naganathan, A. Y. O. Mohamed, and K. N. Mustapha, "Performance of bricks made using fly ash and bottom ash," Constr. Build. Mater., vol. 96, pp. 576–580, 2015.

التنزيلات

منشور

إصدار

القسم

الفئات

الرخصة

الحقوق الفكرية (c) 2025 Abdelkader Fidjah, Kolli Khadidja , Souddi Abdelhak (Author)

هذا العمل مرخص بموجب Creative Commons Attribution-NonCommercial 4.0 International License.

كيفية الاقتباس

Funding data

-

Universidad Nacional de Trujillo

Grant numbers 12/2025